Green Hydrogen Revolution: US Companies Lead Electrolyzer Tech for 22% Emission Cut

The Rise of Green Hydrogen in the US is being spearheaded by companies developing innovative electrolyzer technology, poised to significantly cut emissions by 22% through efficient and sustainable hydrogen production.

The race to a sustainable future is heating up, and **the rise of green hydrogen** is emerging as a key player. US companies are at the forefront, pioneering electrolyzer technology with the potential to cut overall emissions by 22%. But how exactly are they achieving this ambitious goal? Let’s dive in.

Understanding Green Hydrogen and Electrolyzer Technology

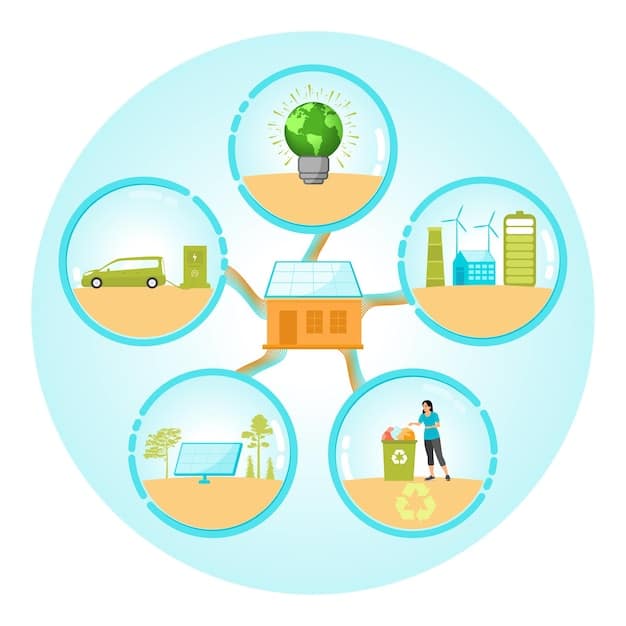

Green hydrogen is produced through the electrolysis of water, a process that uses electricity to split water (H2O) into hydrogen and oxygen. The “green” aspect comes from the source of electricity – renewable sources like solar, wind, and hydro power.

Electrolyzer technology is critical to this process. These devices facilitate the electrochemical reaction, and advancements in their efficiency and cost-effectiveness are driving the expansion of green hydrogen production.

Types of Electrolyzers

Several types of electrolyzers are used in green hydrogen production, each with its own advantages and disadvantages:

- Alkaline Electrolyzers: A well-established technology known for its reliability and use of inexpensive materials.

- Proton Exchange Membrane (PEM) Electrolyzers: Feature rapid startup times and high efficiency, making them suitable for intermittent renewable energy sources.

- Solid Oxide Electrolyzers: Operate at high temperatures, enabling higher efficiencies and potential integration with industrial processes.

The choice of electrolyzer technology depends on factors such as scale, operating conditions, and cost considerations. US companies are investing in research and development across all three types to optimize performance and reduce costs.

In conclusion, green hydrogen production relies on electrolyzer technology powered by renewable energy sources. Different types of electrolyzers offer unique capabilities, driving innovation and expansion in the green hydrogen sector.

US Companies Leading the Electrolyzer Revolution

Several US companies are taking the lead in developing and deploying advanced electrolyzer technology, each contributing unique innovations and strategies.

These companies are not only focused on improving electrolyzer performance but also on scaling up production to meet the growing demand for green hydrogen.

Key Players in the US Electrolyzer Market

Here are some of the notable US companies pushing the boundaries of electrolyzer technology:

- Plug Power: Specializes in PEM electrolyzers and hydrogen fuel cell solutions.

- Nel Hydrogen US: Offers both alkaline and PEM electrolyzers, catering to diverse application needs.

- Bloom Energy: Known for its solid oxide fuel cells, Bloom Energy is also developing solid oxide electrolyzers for green hydrogen production.

These companies are collaborating with research institutions, energy companies, and government agencies to accelerate the development and deployment of green hydrogen projects across the US.

In summary, US companies like Plug Power, Nel Hydrogen US, and Bloom Energy are driving innovation in electrolyzer technology, contributing to the growth of the green hydrogen market and the reduction of emissions.

The 22% Emission Reduction Target: How Green Hydrogen Contributes

The ambitious goal of cutting emissions by 22% relies heavily on the widespread adoption of green hydrogen across various sectors.

By replacing fossil fuels with green hydrogen, industries can significantly reduce their carbon footprint and contribute to a more sustainable energy system.

Sectors Benefiting from Green Hydrogen

Green hydrogen can play a critical role in decarbonizing several key sectors:

- Transportation: Fueling hydrogen fuel cell vehicles, including cars, trucks, and buses.

- Industrial Processes: Replacing fossil fuels in steelmaking, chemical production, and other energy-intensive processes.

- Power Generation: Storing renewable energy and providing dispatchable power during periods of low solar or wind output.

Achieving the 22% emission reduction target requires a concerted effort to deploy green hydrogen technologies across these sectors, supported by policy incentives and infrastructure development.

Challenges and Opportunities in Scaling Up Electrolyzer Technology

While the potential of green hydrogen is significant, numerous challenges must be addressed to scale up electrolyzer technology and achieve widespread adoption.

Overcoming these challenges requires ongoing innovation, investment, and collaboration between industry, government, and research institutions.

Key Challenges Facing Electrolyzer Deployment

Several obstacles hinder the rapid deployment of electrolyzer technology:

- Cost: Reducing the cost of electrolyzers to make green hydrogen competitive with fossil fuels.

- Scalability: Scaling up electrolyzer manufacturing to meet the growing demand for green hydrogen.

- Infrastructure: Developing hydrogen transportation and storage infrastructure to support widespread adoption.

Addressing these challenges will unlock significant opportunities for economic growth, job creation, and environmental sustainability.

Government Policies and Incentives Supporting Green Hydrogen

Government policies and incentives play a crucial role in accelerating the adoption of green hydrogen and supporting the development of electrolyzer technology.

These policies can create a supportive environment for investment, innovation, and deployment of green hydrogen projects across various sectors.

Key Policy Measures for Green Hydrogen

Some of the key policy measures that can drive the green hydrogen economy include:

- Tax Credits: Providing tax credits for green hydrogen production and electrolyzer manufacturing.

- Grants and Funding: Offering grants and funding for research, development, and demonstration projects.

- Regulations: Establishing clear regulations and standards for green hydrogen production and use.

The US government has implemented several initiatives to support the growth of the green hydrogen sector, including the Hydrogen Production Tax Credit and funding for hydrogen hubs.

Future Trends and Innovations in Electrolyzer Technology

The future of electrolyzer technology is bright, with ongoing research and development efforts focused on improving efficiency, reducing costs, and enhancing performance.

These innovations will pave the way for even greater adoption of green hydrogen and its contribution to a sustainable energy future.

Emerging Trends in Electrolyzer Technology

Some of the emerging trends and innovations in electrolyzer technology include:

- Advanced Materials: Developing new materials to improve electrolyzer efficiency and durability.

- AI and Machine Learning: Using AI and machine learning to optimize electrolyzer operation and performance.

- Integration with Renewables: Integrating electrolyzers with renewable energy sources to maximize efficiency and reduce costs.

These advancements will drive the green hydrogen economy forward, making it a more competitive and sustainable energy solution.

The Path Forward: Collaborating for a Green Hydrogen Future

Realizing the full potential of green hydrogen requires a collaborative effort involving industry, government, research institutions, and the public.

By working together, stakeholders can overcome challenges, accelerate innovation, and create a sustainable green hydrogen economy for the future.

Key areas for collaboration include:

- Sharing knowledge and best practices.

- Investing in research and development.

- Developing supportive policies and regulations.

With sustained commitment and collaboration, the US can lead the world in the green hydrogen revolution and achieve its ambitious emission reduction goals.

| Key Point | Brief Description |

|---|---|

| 🌱 Green Hydrogen | Produced via electrolysis using renewable energy sources. |

| ⚡ Electrolyzers | Devices that split water into hydrogen and oxygen. |

| 🏭 US Companies | Pioneering advancements in electrolyzer technology. |

| 🎯 Emission Reduction | Green hydrogen can significantly reduce emissions across sectors. |

FAQ

▼

Green hydrogen is hydrogen produced by splitting water into hydrogen and oxygen using electricity generated from renewable energy sources. This makes it a truly sustainable fuel source.

▼

Electrolyzers facilitate the electrolysis process, using an electrical current to separate water molecules into hydrogen and oxygen. Advanced electrolyzers are crucial for efficient and cost-effective hydrogen production.

▼

Companies like Plug Power, Nel Hydrogen US, and Bloom Energy are leading the charge with innovative electrolyzer technologies and strategies to scale up green hydrogen production across various sectors.

▼

By replacing fossil fuels in transportation, industrial processes, and power generation, green hydrogen can significantly lower carbon emissions, contributing to a 22% reduction target if widely adopted.

▼

Key challenges include reducing electrolyzer costs, scaling up manufacturing, and developing hydrogen infrastructure. Overcoming these hurdles is essential for widespread adoption and a sustainable energy future.

Conclusion

The rise of green hydrogen, powered by innovative electrolyzer technology from US companies, presents a significant opportunity to cut emissions and transition to a more sustainable energy future. While challenges remain, ongoing innovation, supportive policies, and collaborative efforts are paving the way for a cleaner, greener tomorrow.